Paper Coating Machine

Leading Manufacturers, Exporters, Wholesaler and Retailer of Air Knife Coating Head Paper Coating Machine, Blade Coating Head Paper Coating Machine and Gravure Coating Head Paper Coating Machine from Haridwar.

| Business Type | Manufacturer, Trader |

With knife systems, the coating paste is applied onto the carrier or the substrate with a knife or blade. Depending on the desired effect to the knife is countered by a roller, platen or nothing at all; thereby roller knives, platen knives and air knives are distinguished. The knife bar of modern coating plant is equipped with several coating knives and is changeable according to the revolver principle. This facilitates a quick change of the knives, especially of the roller and the air knife. All application systems are equipped with either manually or powered adjustable side scrapers.

In some cases, the side scrapers are completed to a closed paste basin with a front plate, which is necessary especially when low-viscous coating pastes are concerned. Depending on the thickness of the coat to be applied, on the way of the knife's configuration and the viscosity of the paste, knives of different profiles are used.

With knives, the thickness of the coat is defined by:

- Distance between knife and substrate.

- Kind of the substrate to be coated.

- Kind and form of the knives.

- Angle of the knife.

- Position of the knife.

- The viscosity of the paste.

- Speed of the web.

| Business Type | Manufacturer, Trader |

A method by which coating is applied to base paper. The coater consists of a large back-up roll around which the paper passes and at the base of which is the coating pan with an applicator roll applying coating to the paper.

| Business Type | Manufacturer, Trader |

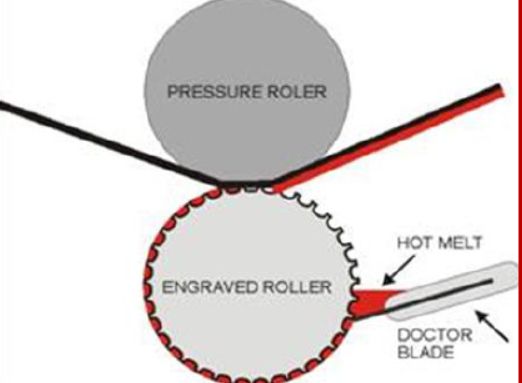

The Gravure Coater has become one of the most popular types of coaters in use today due to its ability to apply less coating with more precision than other methods. There are three types of Gravure coaters: direct gravure, reverse gravure, and differential offset gravure. All three apply a uniform amount of coating across and down the web. In addition, each has its own distinct advantages and disadvantages.

The coat weight produced by the gravure roll varies with the type of coater used. The coat weight is dependent upon the coating solids, coating surface tension, gravure pattern, gravure cell depth, coater configuration and operating speed.